Pavement milling and grinding play a crucial role in maintaining and upgrading infrastructure across urban landscapes. This article delves into the intricacies of these operations, with a particular focus on their significance in Toledo, Ohio. We explore the various machines employed in this process, the essential safety measures and site assessments required for successful operation, and provide a detailed guide on how to effectively manage a milling machine for pavement maintenance. Through a case study examining local projects, readers will gain insights into the practical applications of pavement milling and grinding in Toledo’s roadway infrastructure, underscoring its importance in preserving and enhancing transportation networks.

- Overview of Pavement Milling and Grinding Operations

- The Importance of Pavement Milling and Grinding in Toledo, Ohio

- Types of Machines Used in Pavement Milling and Grinding

- Preparing for Pavement Milling and Grinding: Site Assessment and Safety Measures

- Step-by-Step Guide to Operating a Milling Machine for Pavement Maintenance

- Case Study: Pavement Milling and Grinding Projects in Toledo, Ohio

Overview of Pavement Milling and Grinding Operations

Pavement milling and grinding operations are integral to the maintenance and construction of roadways, providing a critical service in infrastructure development and upkeep. This process involves removing the surface course or other layers of asphalt or concrete from paved areas to prepare for resurfacing, repair, or reconstruction. The specialized machinery used in these operations, known as milling machines or cold planers, precisely cut and collect material, ensuring efficiency and minimal disruption to the surrounding environment. These machines come in various sizes and configurations, suited for different project requirements, from small local roads to major interstates. For instance, in Toledo, Ohio, pavement milling and grinding are conducted by skilled operators who adhere to strict safety standards and utilize advanced technology to achieve optimal results. The collected material is often reused as aggregate in new pavements, promoting sustainability within the construction industry. The precision of these operations is paramount; they must be executed with care to ensure the structural integrity and longevity of the repaired roadways. The success of such projects hinges on the expertise of the operators, the condition of the equipment, and the specifications of the work at hand. In Toledo, Ohio, as in many places, pavement milling and grinding operations are a testament to the ongoing commitment to safe, efficient transportation networks.

The Importance of Pavement Milling and Grinding in Toledo, Ohio

Types of Machines Used in Pavement Milling and Grinding

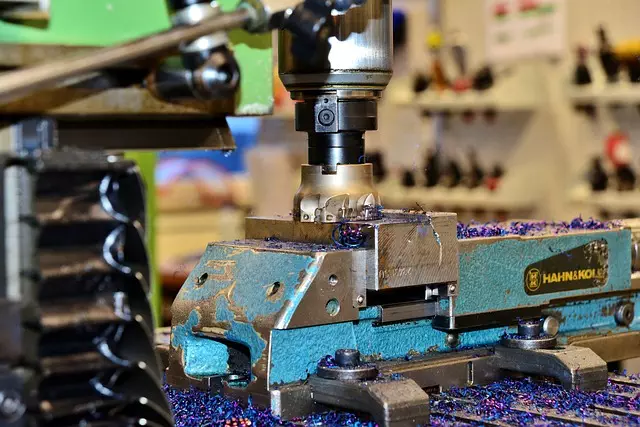

Pavement milling and grinding are essential processes in the maintenance and reconstruction of roadways, facilitated by specialized machinery designed to efficiently remove surface layers of asphalt or concrete. In the realm of pavement milling and grinding, several types of machines are employed, each suited for different tasks. The most common types include milling machines, cold planers, and grinders. Milling machines, often referred to as cold milling machines, are used for the precise removal of asphalt or concrete surfaces, down to specified depths. These machines come in various sizes and configurations, capable of operating on both small-scale projects and large highway construction sites. Cold planers, similar to milling machines, are equipped with a rotating drum fitted with teeth that break up the pavement, which is then conveyed away by a system of augers. This type of machine is particularly effective for larger-scale milling operations.

Grinders, on the other hand, are primarily used for surface dressing or surface treatment applications where the goal is to achieve a specific texture or profile on the road surface. These machines utilize grinding stones or drums to smooth and level the pavement, ensuring the desired texture is achieved for optimal performance. In Toledo, Ohio, these pavement milling and grinding operations are not only critical for infrastructure upkeep but also demonstrate the city’s commitment to maintaining safe and efficient roadways. The expertise of local contractors in handling these machines reflects the importance of this work, as they navigate complex urban environments or tackle expansive rural highway projects with precision and care.

Preparing for Pavement Milling and Grinding: Site Assessment and Safety Measures

When preparing for pavement milling and grinding operations, a comprehensive site assessment is paramount to ensure efficiency and safety. This process begins with careful planning and an evaluation of the pavement conditions, including the type of asphalt, its depth, sub-grade stability, and the presence of any underlying utilities or services. Utilizing advanced technology such as ground-penetrating radar (GPR) aids in identifying potential obstructions that could disrupt the milling process. In Toledo, Ohio, for example, where pavement milling and grinding are common due to its strategic location and infrastructure needs, this step is critical in maintaining project timelines and avoiding costly delays or damage. Safety measures are equally important; trained operators must wear appropriate personal protective equipment (PPE) and follow strict protocols to mitigate risks associated with noise, dust, and heavy machinery operation. Barriers and signage must be set up to alert motorists and pedestrians of ongoing work zones. Moreover, the use of specialized machinery like milling machines and grinders must align with local regulations and environmental considerations, ensuring minimal disruption to both the surrounding community and natural habitats. In Toledo, Ohio, adherence to these safety measures and site assessment protocols is essential for the successful completion of pavement milling and grinding projects, maintaining the city’s infrastructure integrity while prioritizing worker and public safety.

Step-by-Step Guide to Operating a Milling Machine for Pavement Maintenance

When conducting pavement milling and grinding operations, safety and precision are paramount. Operators must first ensure they have a thorough understanding of the machine’s capabilities and limitations. The process begins with setting up the milling machine, which involves positioning it correctly over the designated area of the pavement. Operators should align the cutting head, adjust the depth of cut according to project specifications, and secure the machine to prevent movement during operation. Once the setup is complete, the machine’s control systems are checked to confirm they are functioning optimally, ensuring that the cutting head follows a precise path and achieves the desired depth of milling.

The actual milling process involves controlling the machine’s movements to remove specified layers of asphalt or concrete from the pavement surface. The operator must monitor the feed rate, cutting speed, and depth of cut continuously to maintain the required precision. For instance, in Toledo, Ohio, pavement milling and grinding is a common operation performed by skilled operators who adhere to strict guidelines for asphalt removal and repair. These professionals ensure that the milled material is collected and processed for reuse or proper disposal, further emphasizing the environmental and cost-efficiency benefits of pavement milling and grinding. Throughout the process, the operator must also be mindful of the machine’s vibration and noise levels, utilizing hearing and eye protection as necessary to safeguard personal well-being. Advanced technology in modern milling machines often includes sensors and computer controls that assist operators in achieving a high level of accuracy and consistency, making pavement milling and grinding in Toledo, Ohio, a critical component of infrastructure maintenance and repair.

Case Study: Pavement Milling and Grinding Projects in Toledo, Ohio

In Toledo, Ohio, pavement milling and grinding projects have become a testament to the city’s commitment to infrastructure maintenance and safety. These projects are crucial for repairing and maintaining roadways, ensuring smoother surfaces, and extending the life of the pavement. The process involves removing the top layer of asphalt or concrete from roads, highways, and other paved surfaces using specialized machinery. This not only addresses surface issues but also prepares the way for new asphalt to be laid down, improving overall road conditions.

The city’s recent pavement milling and grinding initiatives have utilized state-of-the-art equipment and technology to efficiently manage these projects. The work is carried out by skilled operators who adhere to strict safety protocols and environmental regulations. These operations in Toledo are a prime example of how effective maintenance can significantly enhance transportation networks, reduce the need for extensive repairs later on, and contribute to the overall efficiency of traffic flow in the city. The data collected from these projects is also used to inform future infrastructure planning and improvements, further underscoring the importance of pavement milling and grinding in Toledo’s urban landscape.